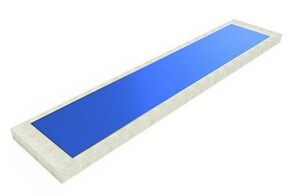

| Length (m) | Width (m) | Height (mm) |

|---|---|---|

| 8 | 3 | 400 |

| 9 | 3 | 400 |

| 15 | 3 | 400 |

| 15 | 3.2 | 400 |

| 18 | 3 | 400 |

| 18 | 3.2 | 400 |

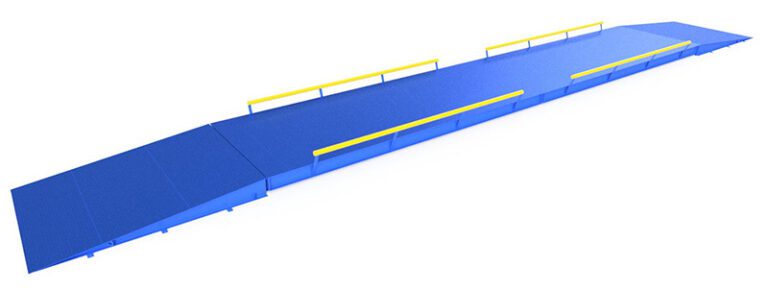

The Highweigh weighbridge has proven itself as an industry leading weighing system in over 30 years of production and service since the base design. With over 2,000 units in operation worldwide, this is the most durable weighbridge on the market today. The HighWeigh weighbridge is a heavy duty beam design, fabricated to the highest standards under strict quality control and factory testing. All joints are fully welded, sealing the internal structure from outside elements, while the external structure is protected with a 3 coat epoxy system. Designed for use as both a static and a portable weigh station when incorporated with our steel sub bases. The HighWeigh can be installed both Pit mounted and Surface mounted.

Available in a multitude of sizes ranging from:

8m x 3m through to 24m x 4m and capacities from 20 tonnes through to 200 tonnes.

Bespoke sizes and capacities are available upon request. SOLAS Ready. ATEX VERSION AVAILABLE.

10mm thick skid resistant Deck Plate enables heavy use eliminating wear problems. A Special Interlocking System positions the deck modules exactly. The decks are fully sealed above and beneath to prevent ingress and have removable plates for easy access to the load cells.

All load cell-bearing plates have triple pass welding to ensure maximum strength, the load cells are mounted under access covers to allow ease of inspection with all load cell cables protected in steel.

Our weighbridges can be installed and integrated with a wide range of peripheral equipment to streamline all your weighing needs, improving productivity as well as site safety and security. Create a completely automated weighing station suited to your needs.

ANPR allows for total Unmanned Weighing and Access control. Automation of the system provides Higher security and safety as the camera is interfaced directly to the Intelligent Indicator. Total Auto capture with no driver intervention required. CCTV Captures loads inside the wagons and vehicles avoiding the weighbridge. Add Vehicle Sensors to ensure the vehicle is completely within the weighing area. Unmanned Weighing Terminals comprise of transponders to read Vehicle RFID fobs, Digital weight readout & ticket printer.

Libra sells and hires out weighbridges to a broad range of clients across the UK and worldwide in a range of industries including mining, excavation, reclamation, construction, waste management and demolition among others.

Libra can offer you unbeatable savings with our new monthly payment plans, you will end up paying less than cash price! Talk to our sales team today to find out how.

We use cookies to support your experience throughout this website. Learn more.